Our Capabilities

A comprehensive suite of in-house capabilities, ensuring quality control and innovation at every stage of the manufacturing process

Our End-to-End Process

From concept to delivery, our integrated approach ensures quality and precision at every step

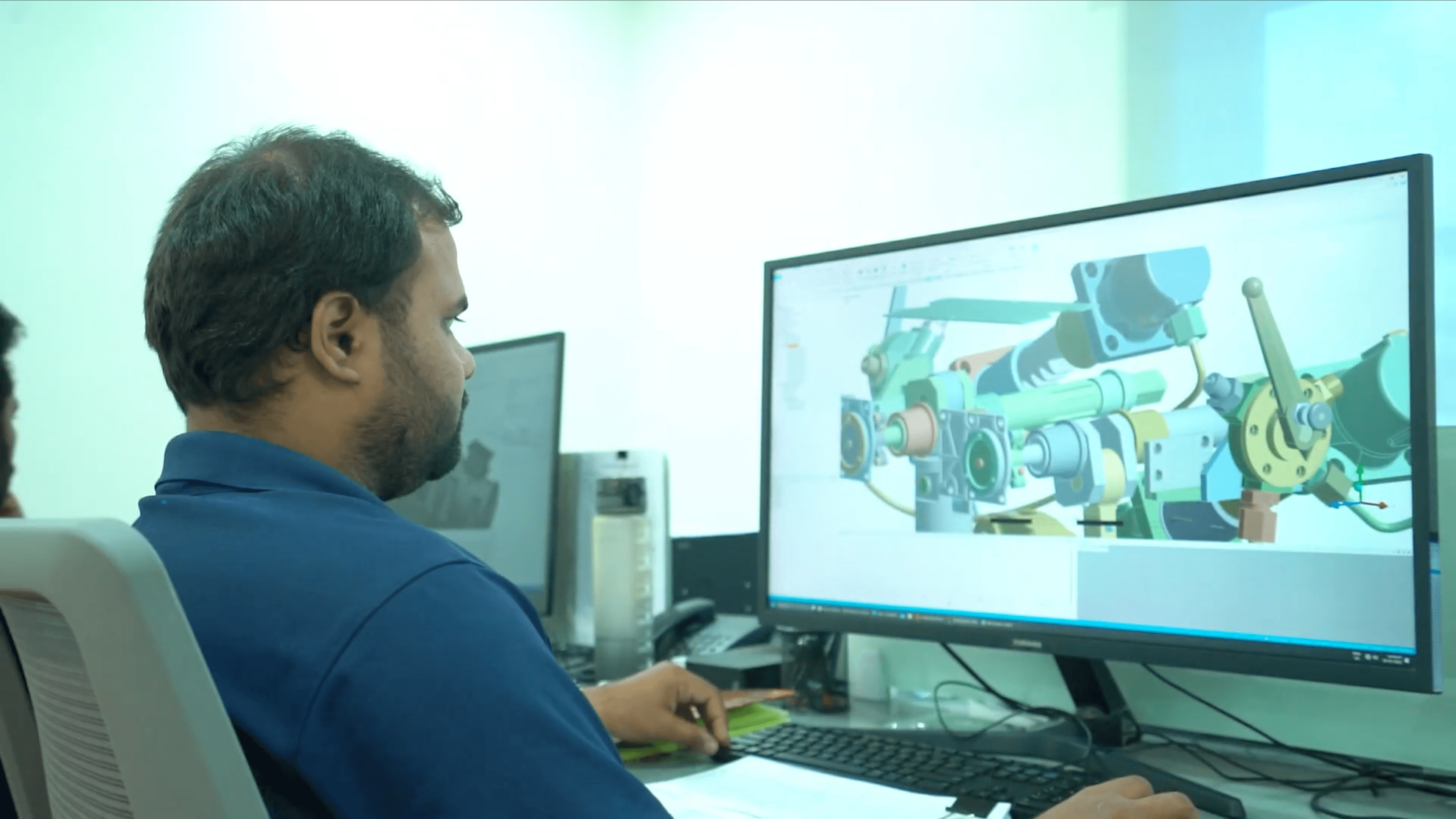

Design

Starting with concept development and detailed engineering design

Analyze

Validating through FEA, CFD and simulations for optimal performance

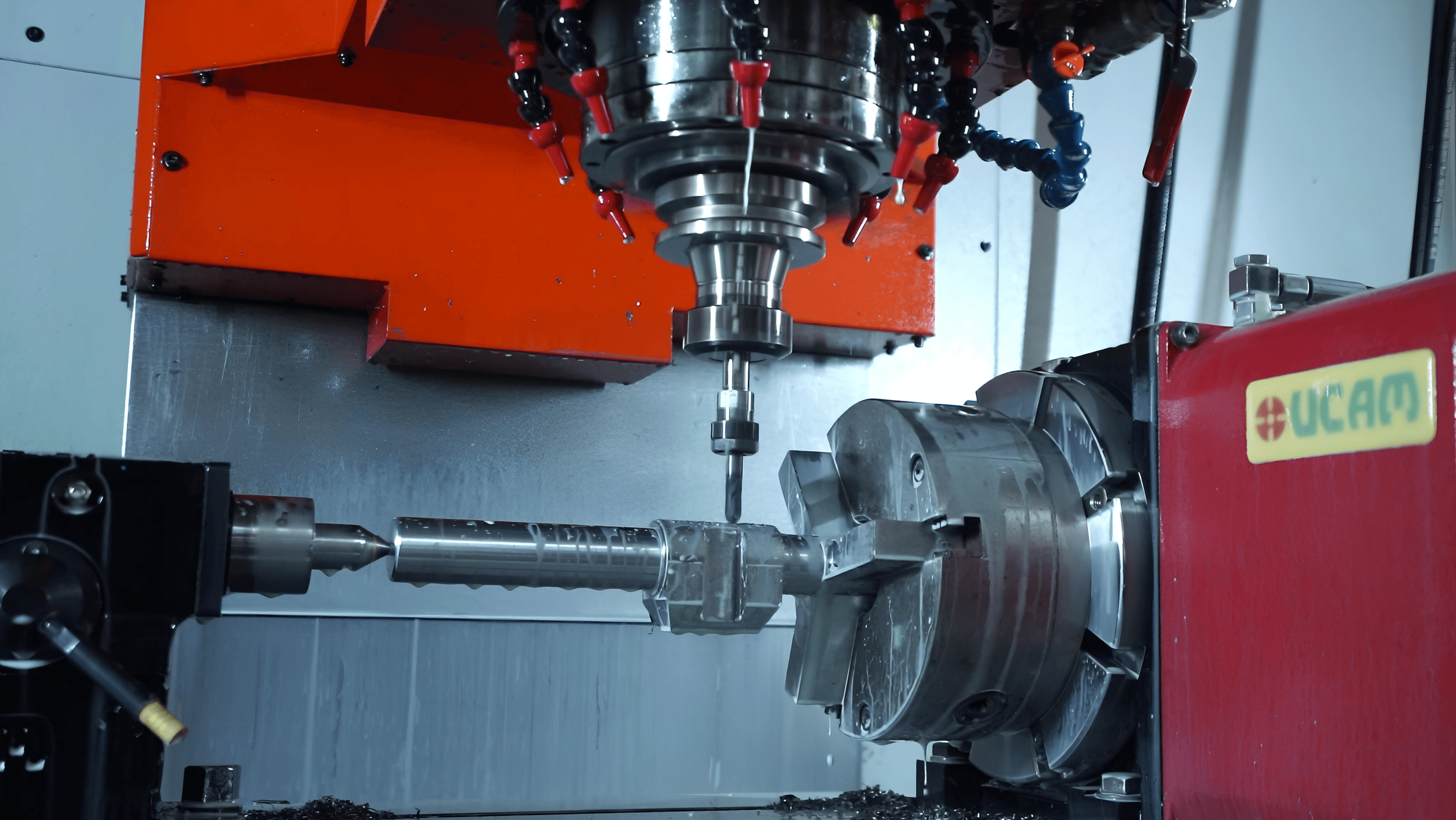

Manufacture

Casting, Forging, Precision Machining and fabrication to exact specifications

Test

Rigorous testing under simulated and actual operating conditions

Deliver

On-time delivery with comprehensive documentation

Our Core Capabilities

Discover our comprehensive range of in-house manufacturing capabilities that ensure complete quality control throughout the production process

Design & Development

From concept to prototype, we bring your ideas to life with precision and innovation.

- Concept Design & Engineering

- 3D Modeling & Analysis

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- Prototyping & Rapid Development

- Reverse Engineering Capabilities

Precision Machining & Fabrication

Achieving micron-level accuracy on complex geometries with advanced multi-axis machining.

- Expertise with Titanium, NAB, Inconel, Maraging Steels & Special Alloys

- Single setting 3, 4, and 5 axis machining

- Tolerances up to 2 microns

- Complex geometrical components

- High-precision components for critical applications

Specialized TIG Welding

Certified and specialized welding in clean environments for critical materials and applications.

- Titanium welding in Argon purged environment

- Expertise with Copper Alloys, Stainless Steels & Inconel

- 6G Certified Welders for Nuclear Grade Welds

- Custom fixture design and manufacture

- Welding of exotic materials including Zirconium & Hastelloys

Casting

In-house foundry producing reliable, high-quality castings for various applications.

- Materials: Copper Alloys, Alloy Steels & Stainless Steels

- Sand Casting: 1kg to 100kg (up to 1.3 tons with partners)

- Investment Casting: 50g to 35kg

- Compliance with GosStandart, NES, ASTM standards

- High integrity castings for critical applications

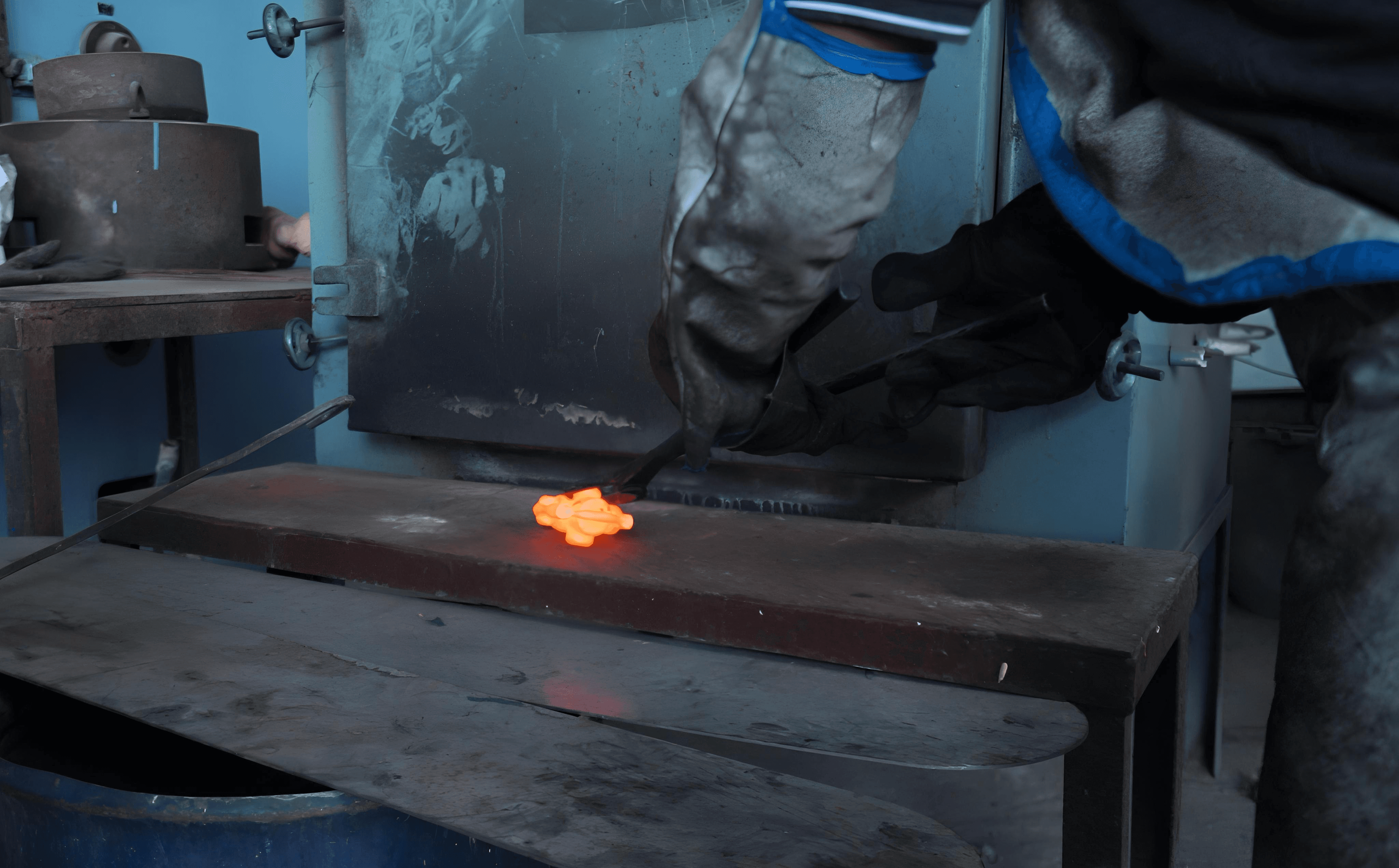

Forging

Expertise in hot forging for components requiring high material integrity under stress.

- Materials: Titanium, Alloy Steels, Stainless Steels & Copper Alloys

- Applications for high-stress, high-pressure (up to 600 Bar)

- Maximum 300mm Diameter

- Components up to 20Kg

- Superior grain flow for enhanced structural integrity

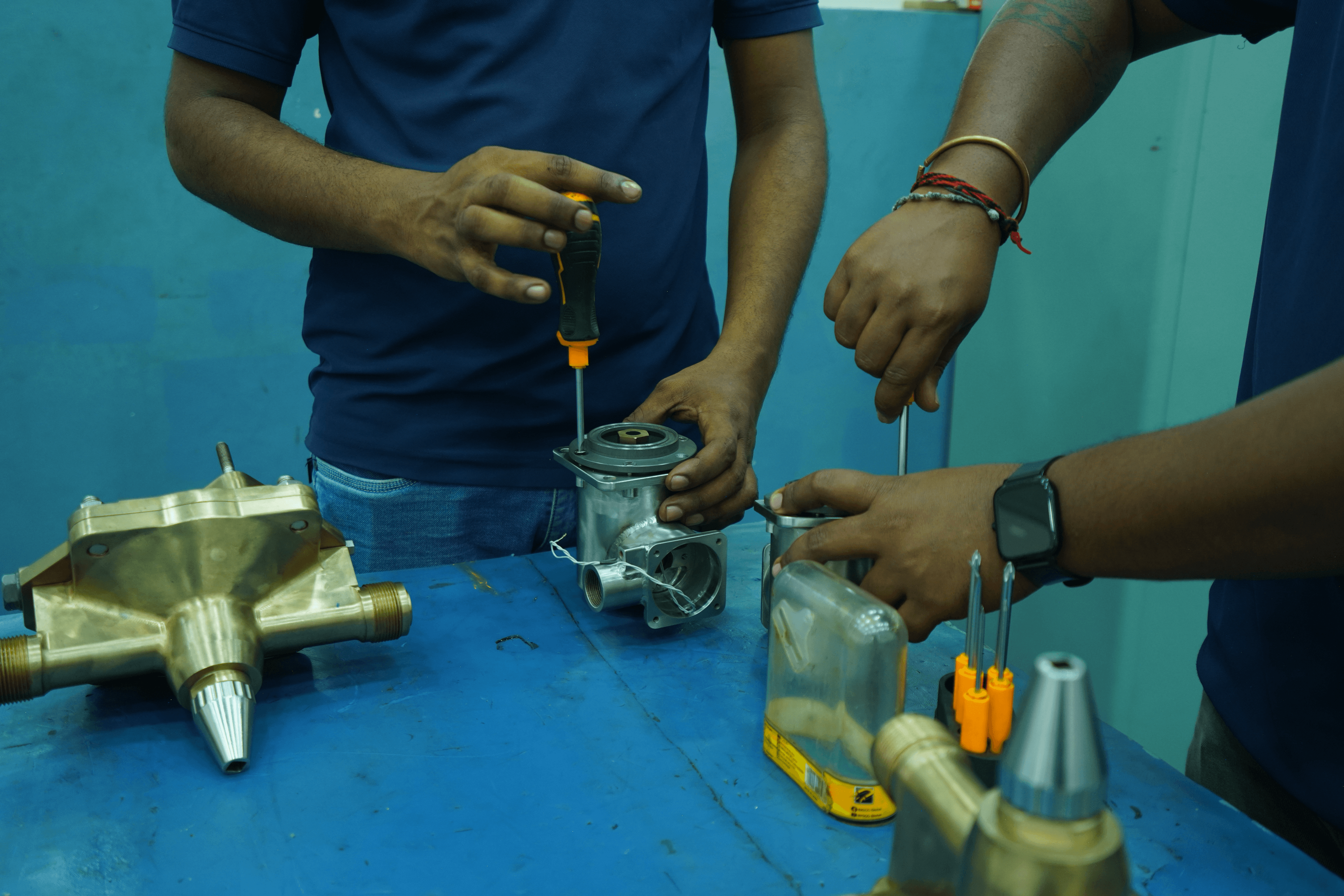

Assembly & Cleanroom Operations

Dedicated facilities for assembling sensitive and complex components with precision.

- 10,000 Class Cleanroom (1500 sq ft)

- Custom assembly fixtures and tools

- Precision and repeatability in assembly processes

- Critical component handling protocols

- Contamination-free assembly environment

Heat Treatment & Surface Treatment

In-house capabilities to enhance material properties and component finishes.

- Comprehensive Heat Treatment processes

- Anodizing (including Titanium)

- Quenching & Tempering

- Surface finishing for optimal performance

- Treatments for corrosion resistance and durability

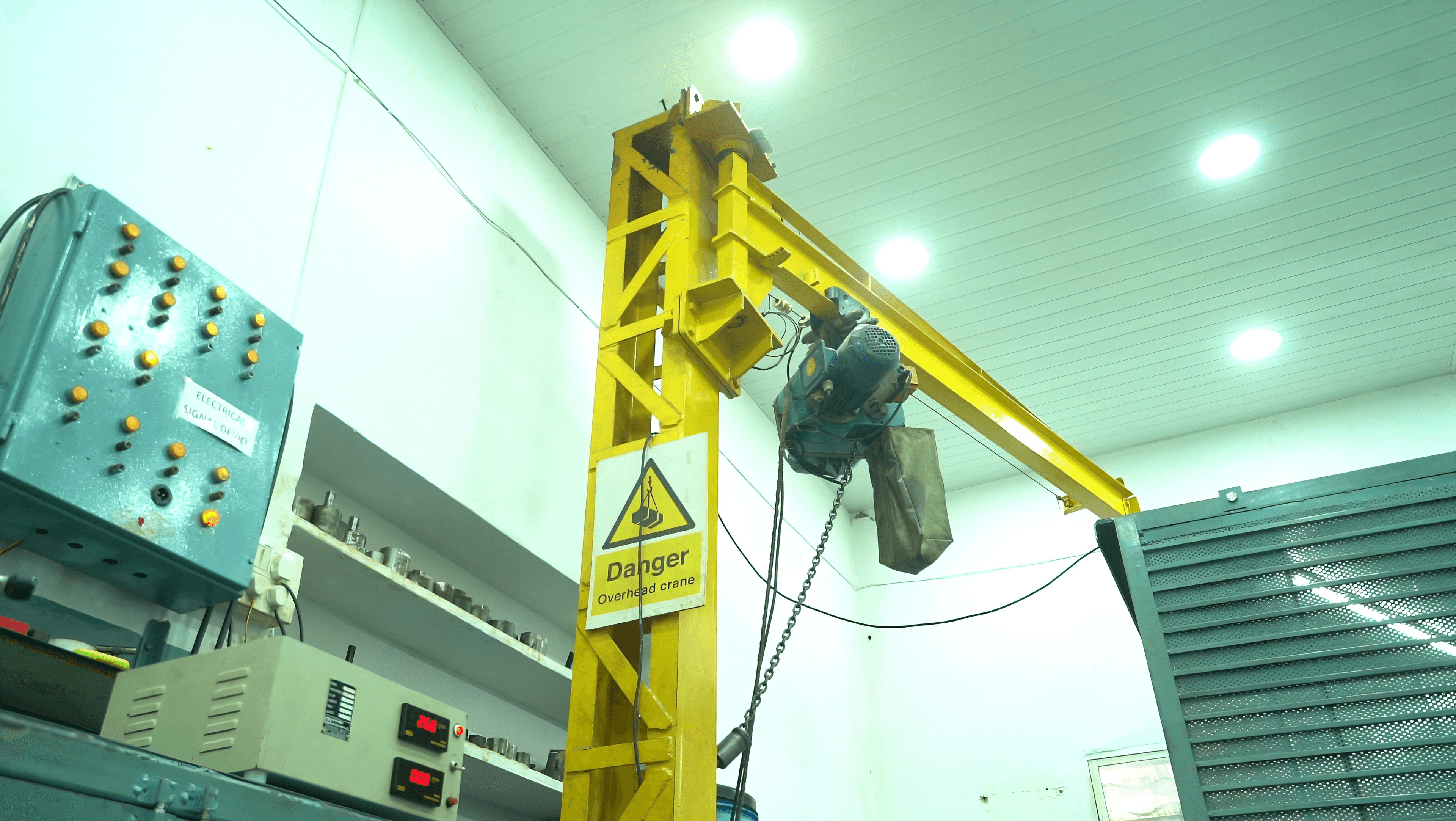

Testing & Quality Assurance

Rigorous testing procedures to validate performance and reliability under demanding conditions.

- Non-Destructive Testing (NDT) & Dye Penetrant Testing (DPT)

- High-Pressure Pneumatic (400 Bar), Hydraulic (1000 Bar) & Hydraulic Cyclic (500 Bar) Testing

- Specialized tests: CV & Fuel Injection

- CMM facility with FARO ScanArm for 3D inspection

- Level 2 & 3 Radiography with certified partners

Value Added Services

Extending our support beyond manufacturing through the entire product lifecycle.

- Installation, STW & commissioning expertise

- Post-delivery support

- On-time delivery of customized products

- Superior quality with high consistency

- Spares support throughout product lifecycle

Quality Certifications

Our capabilities are backed by international quality certifications and standards

ISO 9001:2016

Quality Management System

EN9100

Aerospace Quality Management